Mon – Fri: 8AM – 4.30PM

Saphex Unit 2, Prospect Works, Darnall Road, Sheffield, S9 5AH

Call Us:

Shell and Tube Heat Exchangers

Industrial Shell & Tube Heat Exchangers

Shell & Tube Heat Exchangers have been the backbone of heat transfer for many years. Having been used over the decades, a reliable source of data and wealth of knowledge is readily available, making them a popular choice in many applications.

Manufactured from a variety of materials such as stainless steel, Steel & Titanium in a number of designs these heat exchangers offer a wide scope to the designer of the heat transfer system.

Due to the longevity of the unit the designer usually makes adequate provision for routine maintenance such as cleaning and inspection which is of the upmost importance for the performance of any system.

Saphex Provide a full back up service for shell & tube heat exchangers including cleaning, servicing, re-tubing, manufacture, installation & design.

All work is carried out by our fully trained staff and can be carried out either in our workshop or on site.

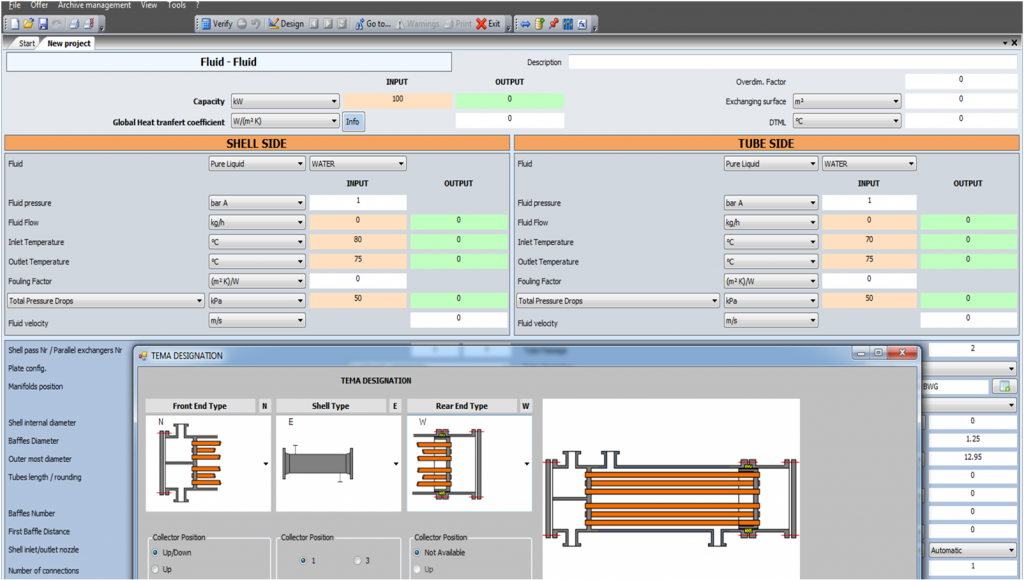

Designing shell and tube heat exchangers

Here at Saphex with the help of our design software we can quickly provide quotes and produce the best quality heat exchanger for our clients requirement ensuring performance is guaranteed. This also provides a TEMA (Tubular Exchanger Manufactures Association) print out to ensure our customers peace of mind that we are working to industry standards.

We also have design engineers who have been working in this industry over 35+ years.

If you’re looking for high-quality shell and tube heat exchangers, look no further than Saphex. Our products are designed to meet the needs of a wide range of industries, including chemical processing, power generation, and more. With years of experience in the field, we pride ourselves on offering some of the best heat transfer solutions on the market. Our heat exchangers are built to last and are backed by a team of expert engineers who can help you find the right solution for your specific needs. So whether you need a heat exchanger for a new project or are looking to replace an existing unit, Saphex has you covered. Contact us today to learn more about our products and services and how we can help you optimize your heat transfer operations.

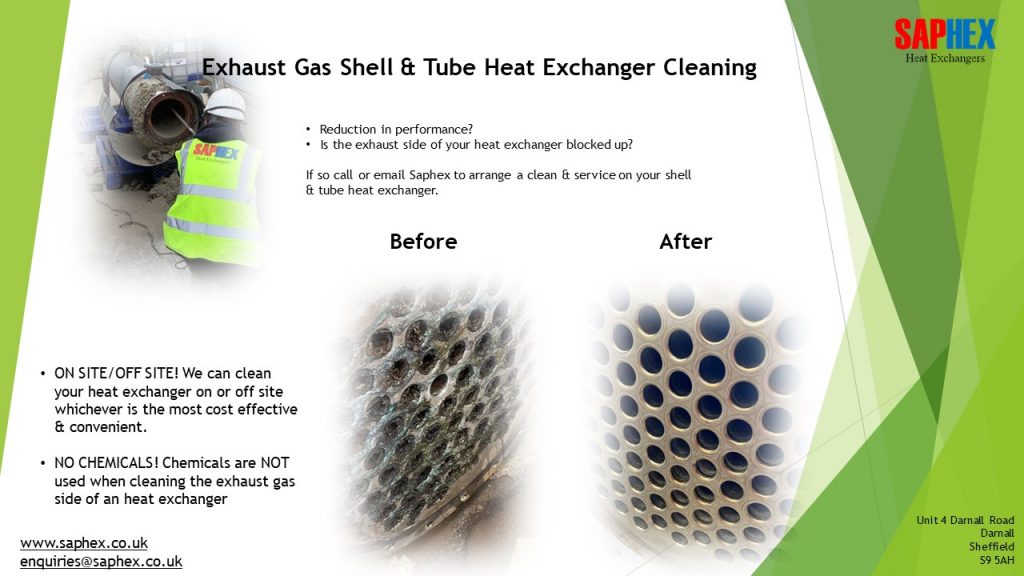

Exhaust Gas heat Exchangers

You can utilize a exhaust gas shell & tube for heat recovery using the heat from your exhaust to warm a fluid on the other side of the heat exchanger which can be used in which ever process you have on site. This save’s mega cost on utility bills. Saphex can also work out the cost savings for you please just ask.

Saphex has extensive knowledge of exhaust gas shell & tube heat exchangers with years of maintaining and cleaning we understand the problems you face. we build our shell & tubes to the best design for your system. You will get guaranteed performance with our shell & tubes.

Shell & Tubes Vs Plate Heat Exchangers

Shell & tube heat exchanger although they usually have a larger footprint and a higher capital cost than a plate heat exchanger these can often be a better solution for many applications.

Plate heat exchanger are sold on the benefits of capital cost, efficiency and ease of maintenance. It’s fair to say that the capital costs are usually lower, however efficiency should not to be confused with physical size as it is the power required to move the liquids that determine the efficiency and there is no difference between the two. With regard to servicing then due to the cost’s of the gaskets on plate heat exchanger then the servicing on shell and tube units is often lower and less frequent.

- Cost: Shell & tube (Long Term) Plate exchanger (Short term)

- Quality: Shell & tubes

- Size: Plate heat exchangers

- Serviceability: Shell & tube

Exhaust Gas Shell & Tube Cleaning

Shell & Tube Quick Pricing Form

Shell & Tube manufacturing